Stampiave

UMFORMUNG & ZUSAMMENBAU

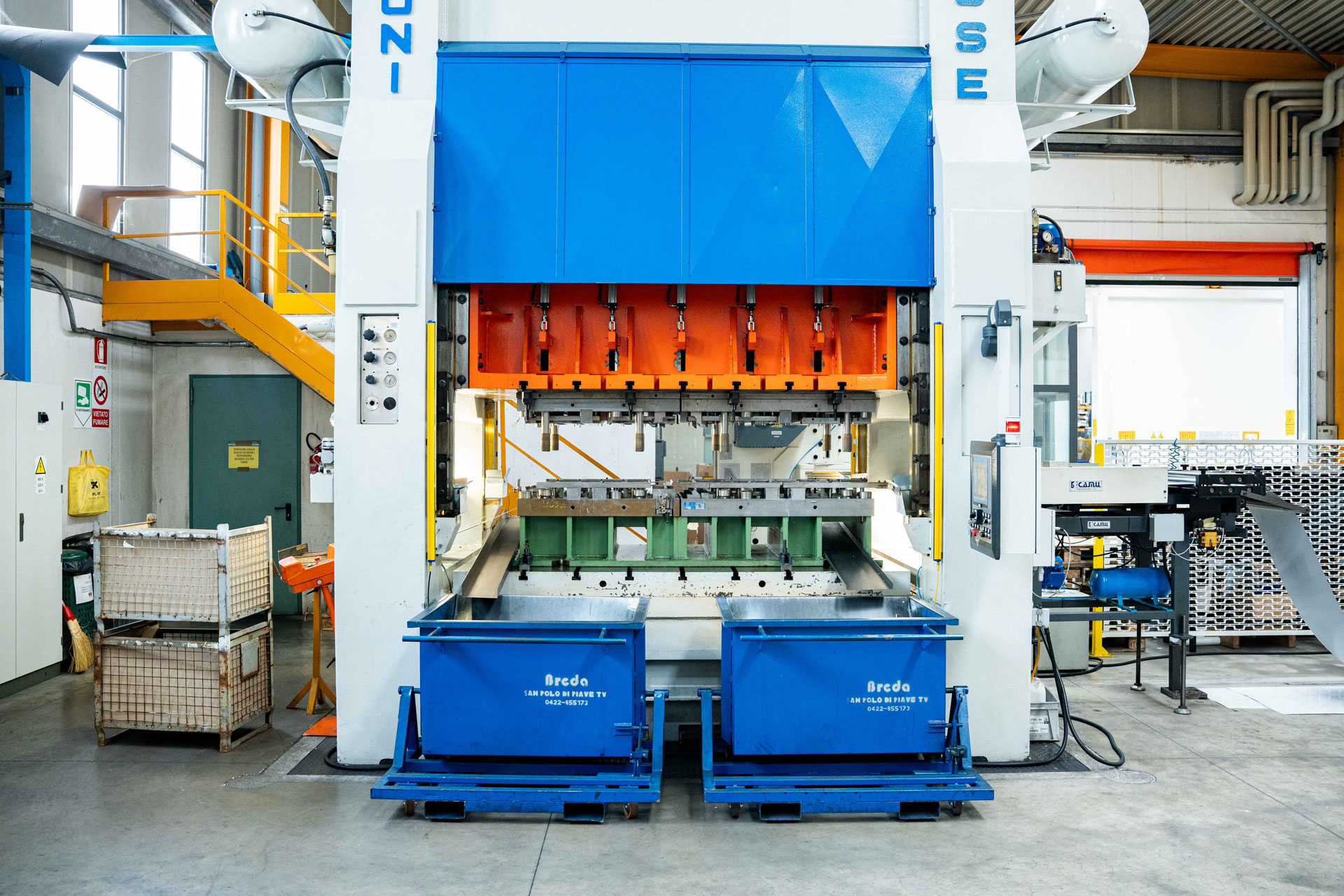

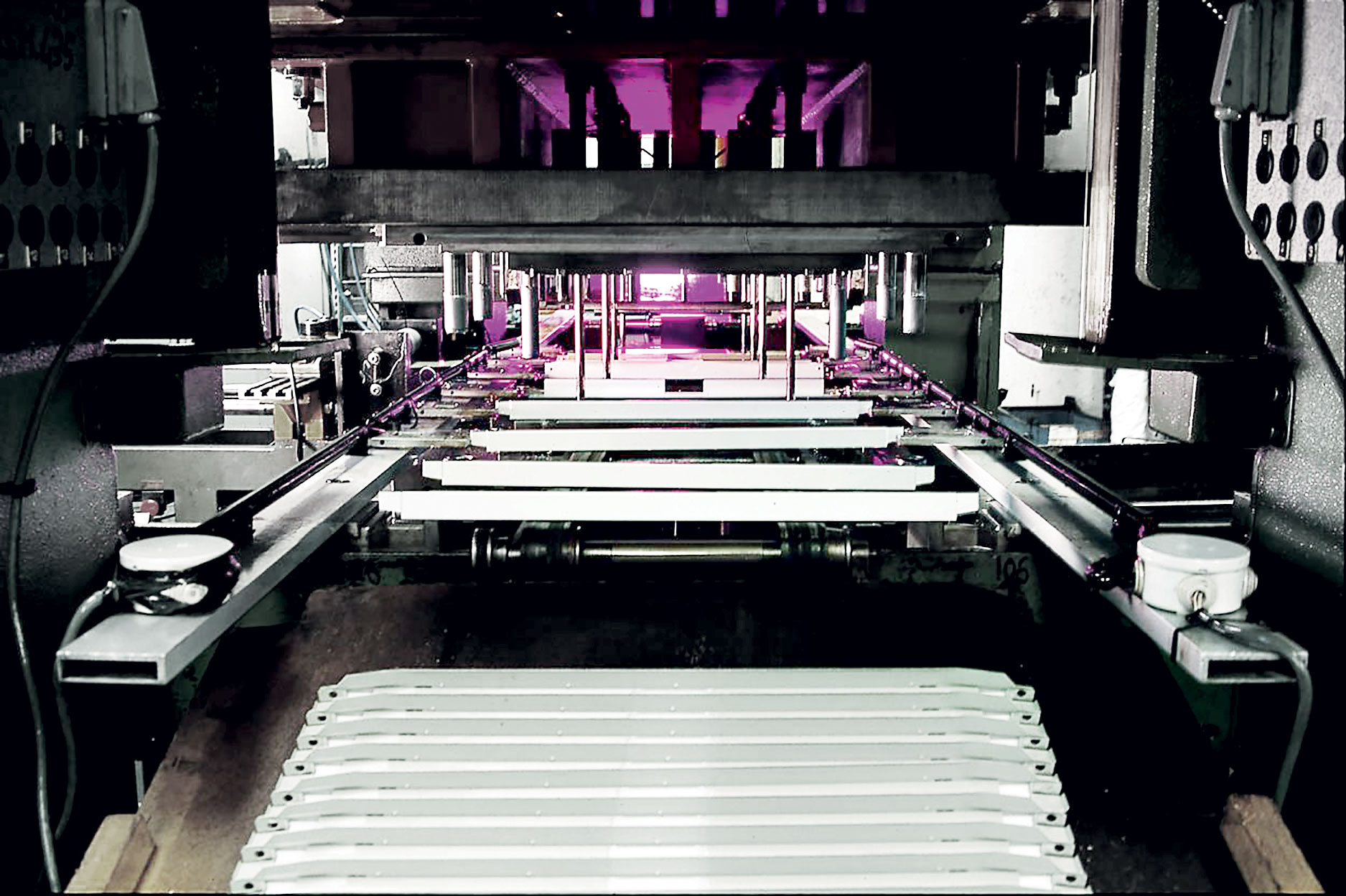

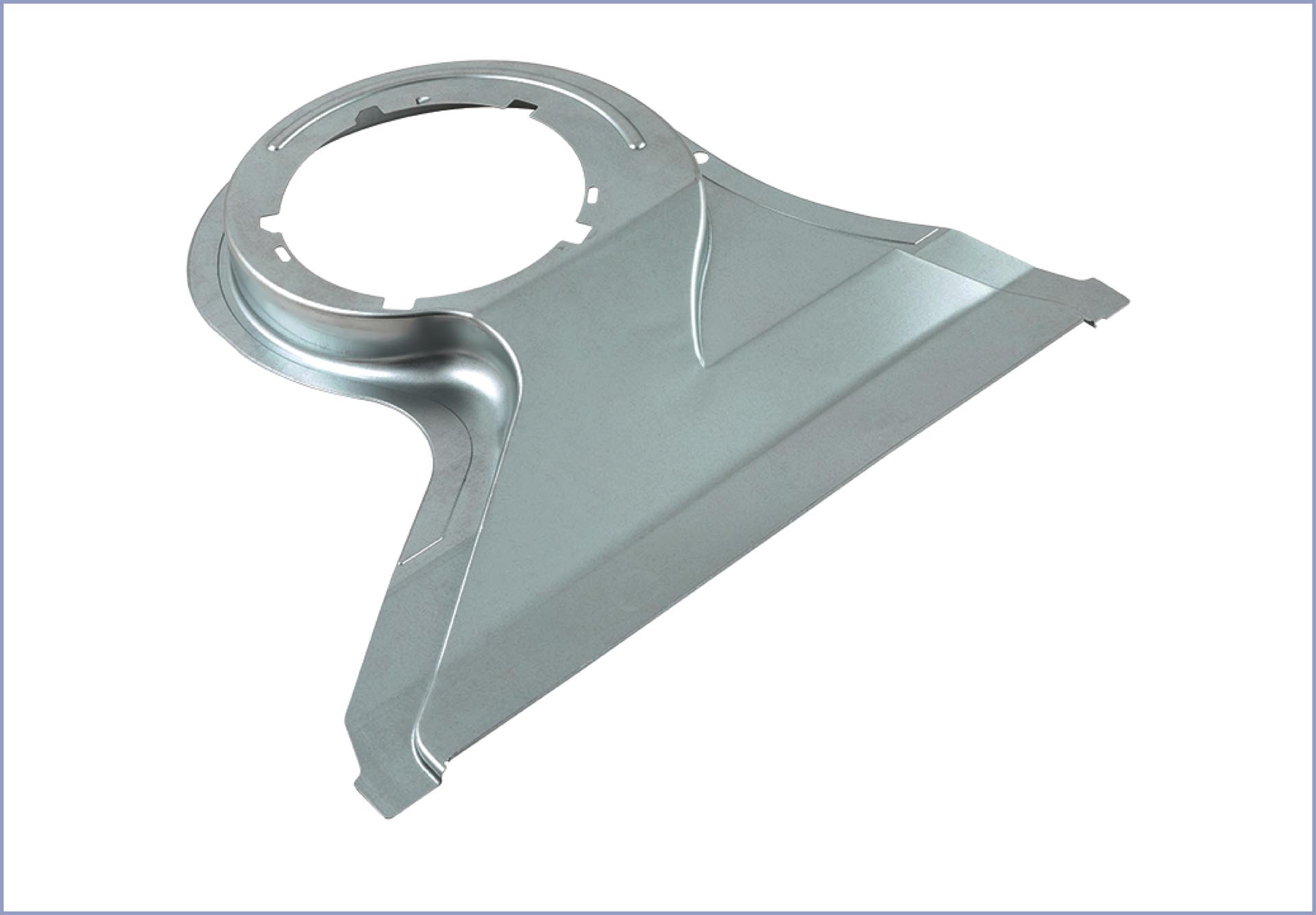

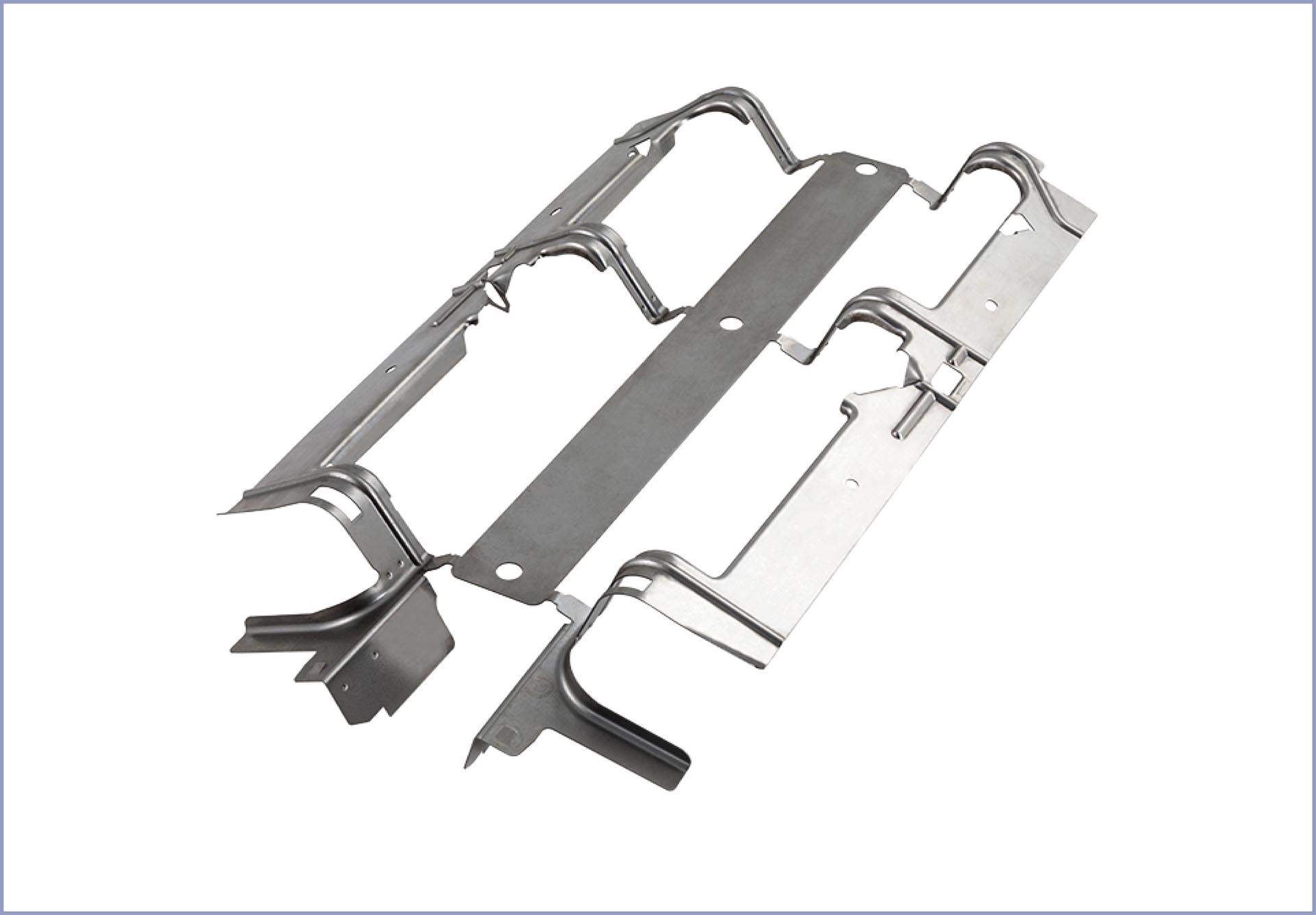

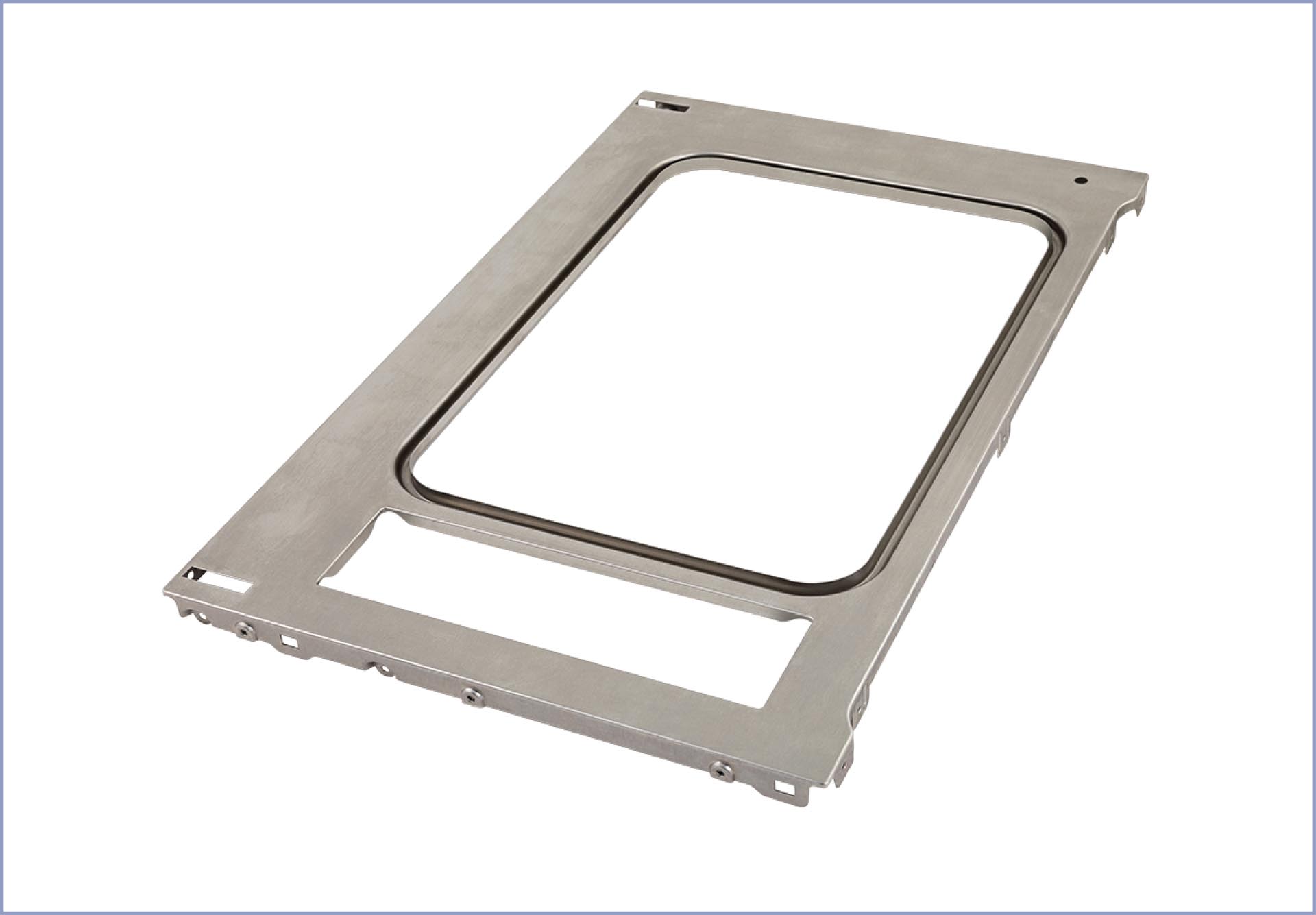

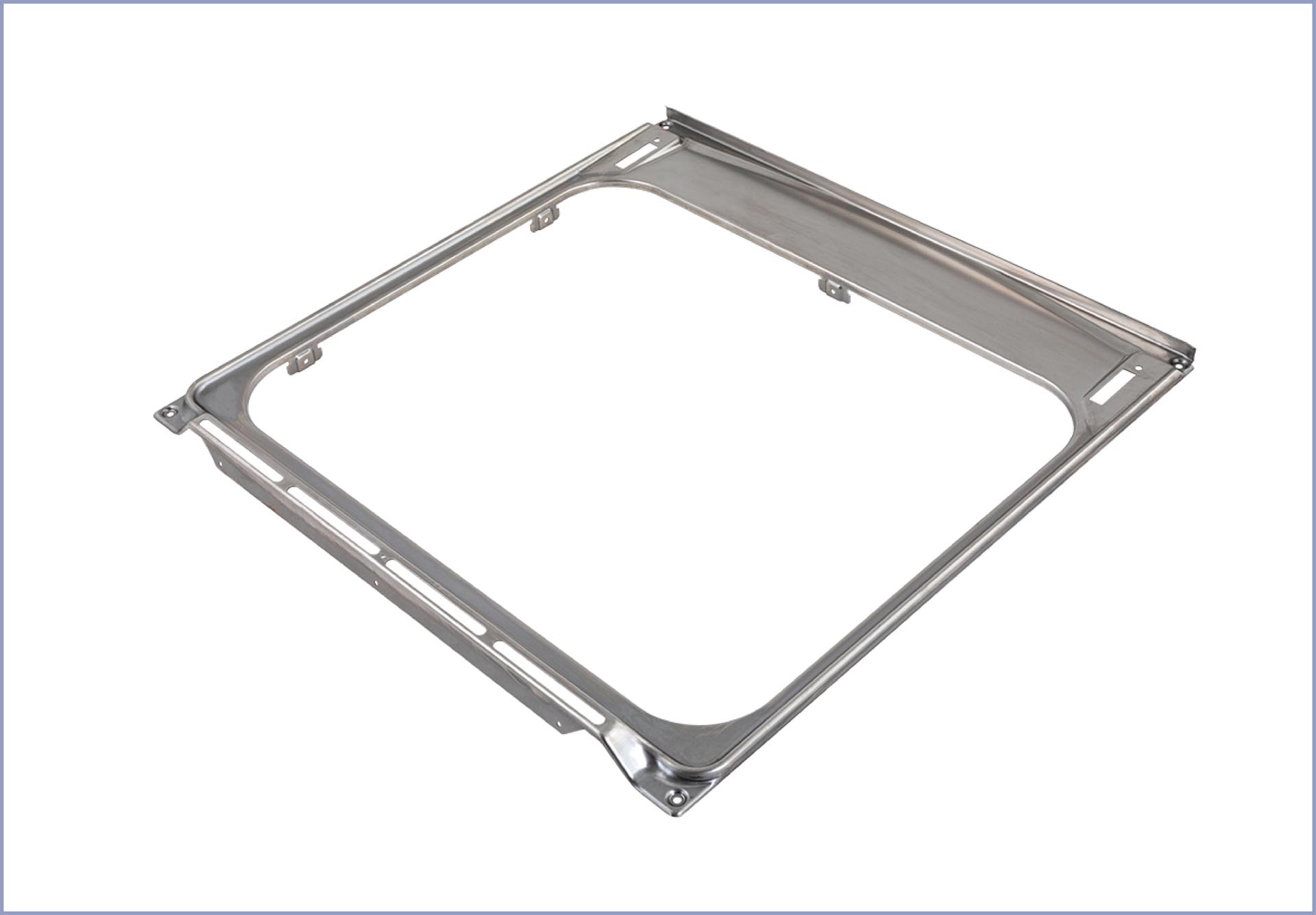

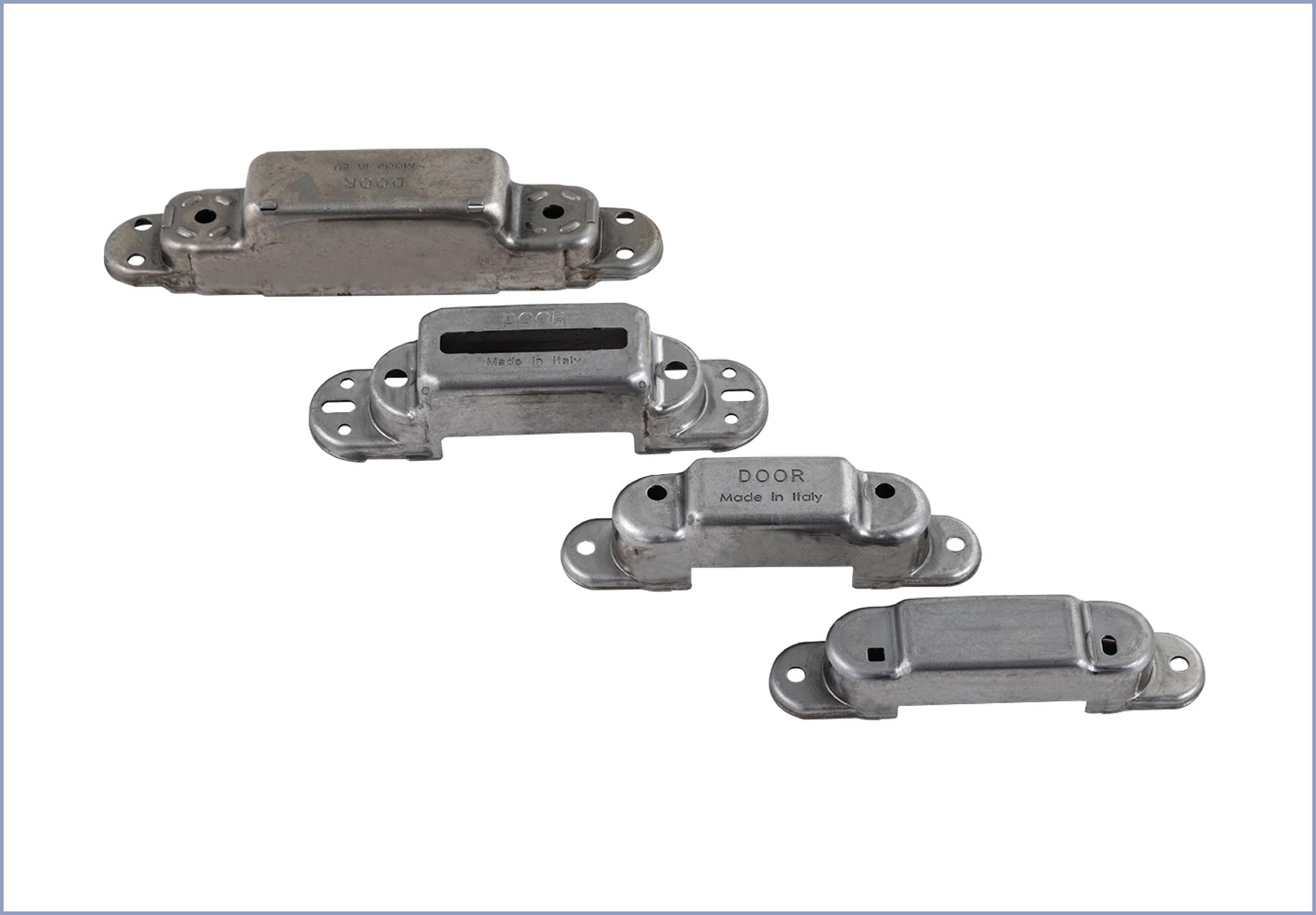

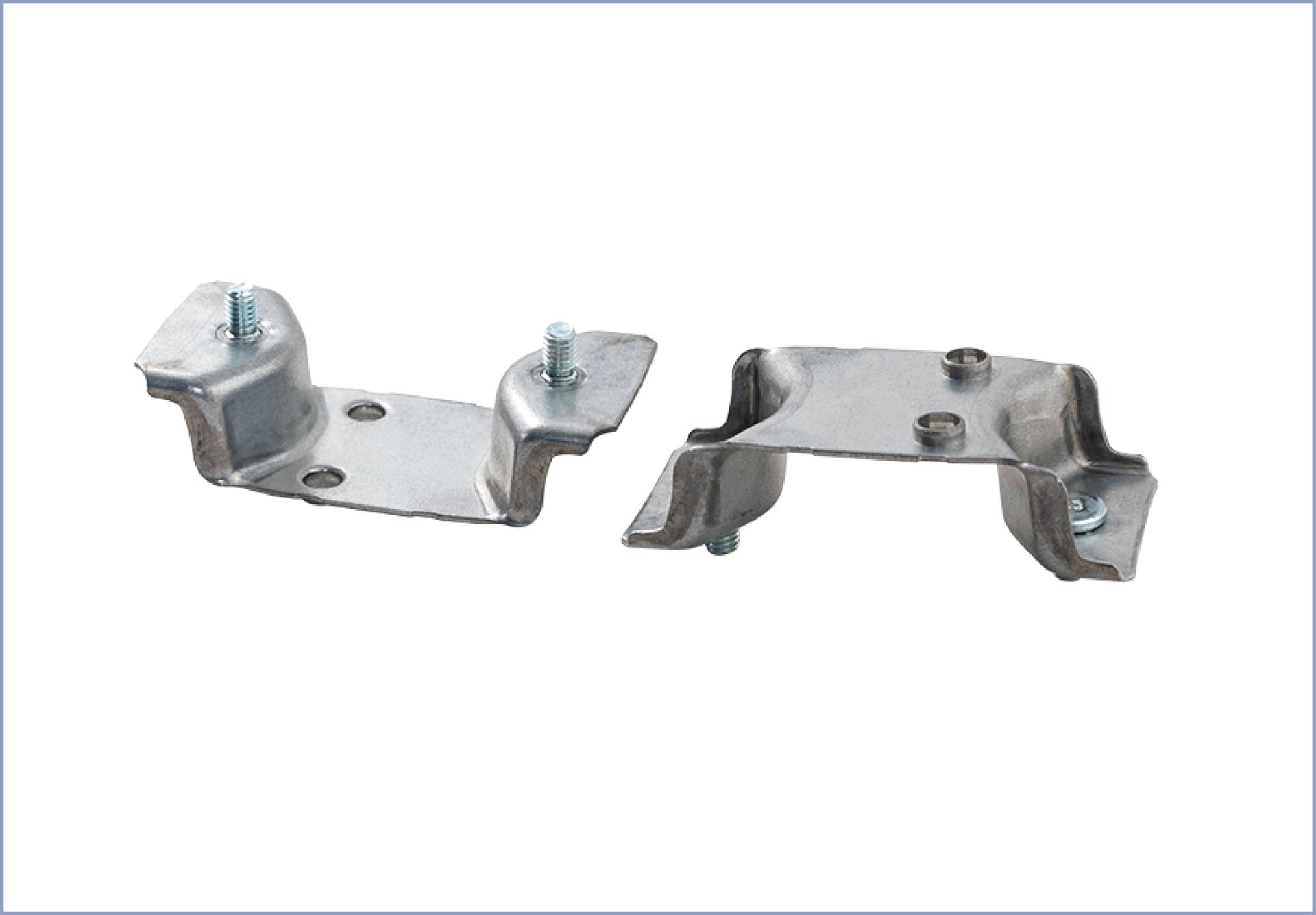

The company produces using a fleet of 40 presses from 30 to 1.250 tons that transform iron, steel, aluminium, copper and brass from 0.2 to 6 mm thick. The machines are equipped with belt feed lines up to 1,300 mm wide and 5 mm thick.

The presses are all of the latest generation so as to guarantee high productivity and excellent competitiveness.

To safeguard the integrity of the moulds, all the presses are equipped with electronic safety devices.

The company is able to provide surface finishing treatments, according to the customer's needs (painting, galvanizing, anodizing, sandblasting, cataphoresis, etc.), with the collaboration of qualitatively selected suppliers.